In the fast-paced world of manufacturing, staying ahead is not just a goal; it’s a necessity. One of the key factors propelling industries forward is the adoption of rapid tooling, a game-changing approach that ensures efficiency, precision, and a competitive edge. Let’s delve into the transformative world of rapid tooling and discover how it’s reshaping the landscape.

Understanding the Essence of Rapid Tooling

In the dynamic landscape of manufacturing, where time is of the essence, traditional tooling methods often fall short. This is where rapid tooling steps in as a beacon of innovation. It involves the swift creation of molds and tools using cutting-edge technologies, minimizing lead times, and maximizing productivity.

The Bold Impact on Production Timelines

Accelerating Time-to-Market

In a market driven by speed, rapid tooling slashes the conventional timelines associated with tool production. The ability to swiftly iterate and create molds translates to a significantly reduced time-to-market for new products. This agility is a competitive advantage that no modern business can afford to overlook.

Precision at Unprecedented Speeds

Precision is the hallmark of quality, and Rapid Tooling ensures that this is achieved without compromising on speed. The advanced technologies employed in this process guarantee the creation of intricate molds with unmatched accuracy, setting a new standard for manufacturing excellence.

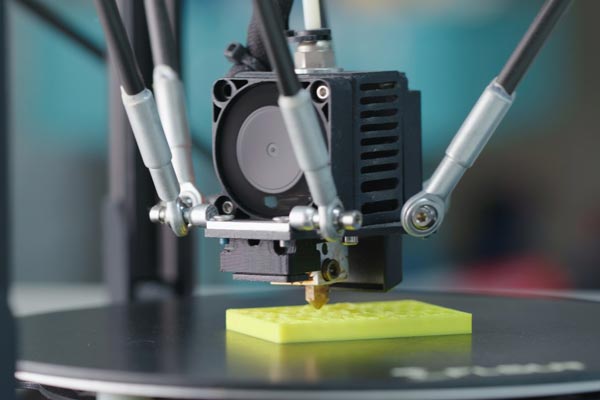

3D printing machine

Embracing Sustainability Through Efficiency

Waste Reduction and Cost-Efficiency

Rapid tooling is not just about speed; it’s also about resource optimization. The precision in design and production minimizes material waste, contributing to a more sustainable manufacturing process. This dual benefit of efficiency and cost-effectiveness makes it a strategic choice for forward-thinking enterprises.

Flexibility in Design Iterations

The rapid iterations made possible by this technology empower designers to experiment and refine their creations without prolonged waiting periods. This flexibility not only fosters innovation but also ensures that the final product aligns seamlessly with market demands.

Overcoming Challenges with Technological Prowess

Addressing Complex Geometries

Traditional tooling methods often struggle with intricate designs and complex geometries. Rapid tooling, powered by advanced software and machinery, conquers these challenges with ease. It opens up new possibilities for designing products that push the boundaries of what was once considered feasible.

Customization Without Compromise

In an era where personalization is key, rapid tooling stands out for its ability to facilitate customization without compromising efficiency. Whether it’s a unique component or a specialized part, the technology adapts to the diverse needs of modern manufacturing.

A Paradigm Shift in Manufacturing

In conclusion, rapid tooling is not just a method; it’s a paradigm shift in the manufacturing landscape. Its fusion of speed, precision, and sustainability catapults businesses into a realm of unparalleled competitiveness. Embrace the future of manufacturing – embrace rapid tooling for a journey marked by efficiency, innovation, and success.