Additive Manufacturing

Instant Quotes & DFM Feedback

Free DFM Feedback With Your Quote

Parts as Fast as 2 Days

What is Additive Manufacturing?

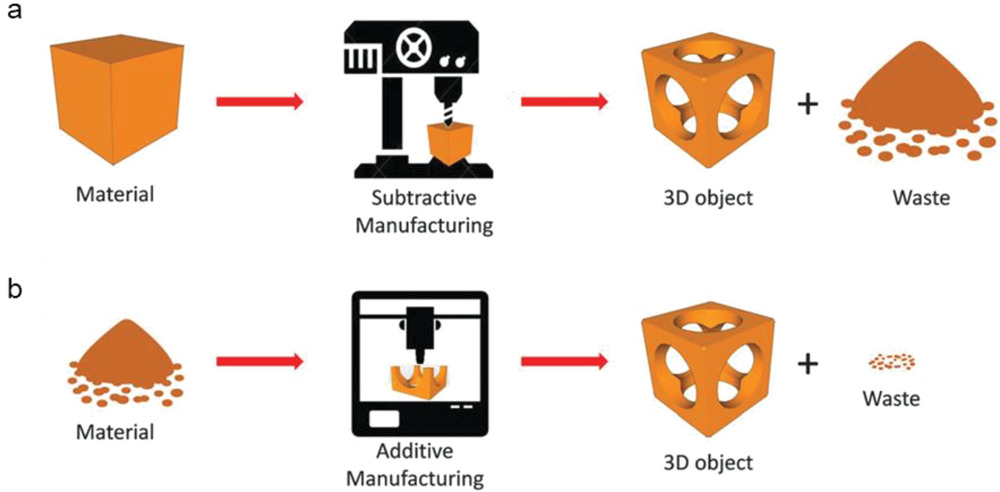

Additive manufacturing, which is also referred as 3D printing, is an appropriate way to represent the technique that make parts by adding materials in layer by layer. It is built from a CAD model. This technique has significantly evolved in not only the manufacturing industry, but almost every field. Additive manufacturing is recognized as a technology for “prototyping”. Because the geometry of a part can be easily restructured, for those who have a desire for the customized parts, it offers more personalized solution.

How Many Steps in the Process

There are several separate AM processes, each with its own set of criteria, which include:

- Binder Jetting

Binder jetting is a family of additive manufacturing processes. It uses a screen printing head that moves on the x, y, & z dimensions to deposition alternating coatings of particles and a viscous binder as an adhesion. And spray various colors with multiple nozzles so that multicolor parts printing can be realized in this method.

- Deposition of Directed Energy

This method allows for the creation of parts by melting the materials by a laser, electronic beam and electric arc. This printing way is used extensively in aerospace. It can be able to direct the deposition of small areas with high precision.

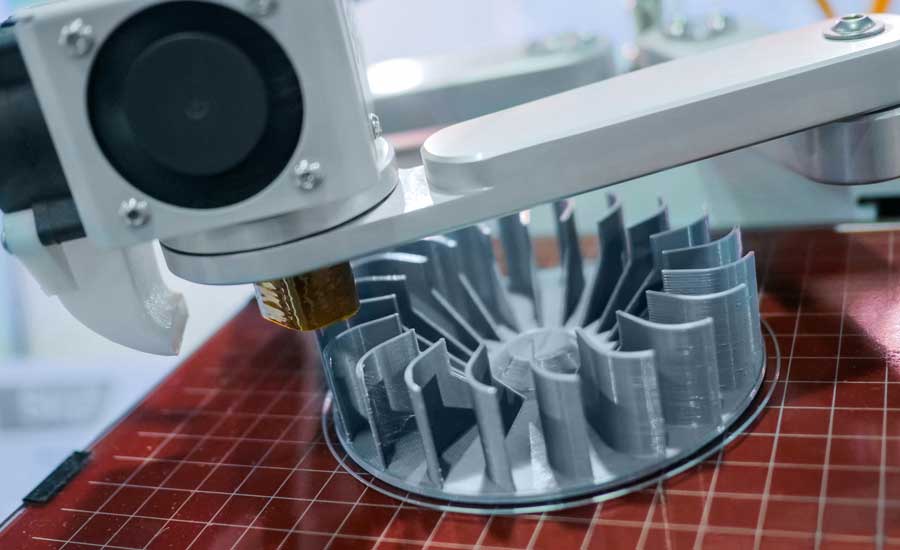

- Extrusion of Material

Material extrusion is a crucial additive manufacturing. It achieves to make 3D parts through a nozzle. In the nozzle, the materials would be heated to soften. And then, they would be deposited onto the platform layer by layer.

- Sheet Lamination

Sheet lamination is also called ultrasonic additive manufacturing (UAM) or laminated object manufacturing (LOM). It heaps up the thin sheet of materials and bond them together by using the ultrasonic welders. UAM may be operated with various metals, including aluminum, alloy steels and titanium.

Advantages of the Process

Utilization Ease

Compared with CNC machining, 3D printing is more friendly than it in the sector of utilization. After finishing the template, there is no need for supervision when the printing begins. The scanner can be unattended until the part is complete. What’s more, the printer is quite easy to use. It is possible to have a small volume production.

Cheapest Budget

The costs of 3D printing depend on its volume of needed materials. In many manufacturing methods, it can be said that 3D printing is the cheapest way when we want to product parts in small quantities. It is ideal for rapid prototyping.

Accessibility

It is also more accessible in our production lines. 3D printers are easily to acquire, maintain and operate.

Reducing the amount of material used

It does not need to consider the waste of operation because there is no waste that would be generated.

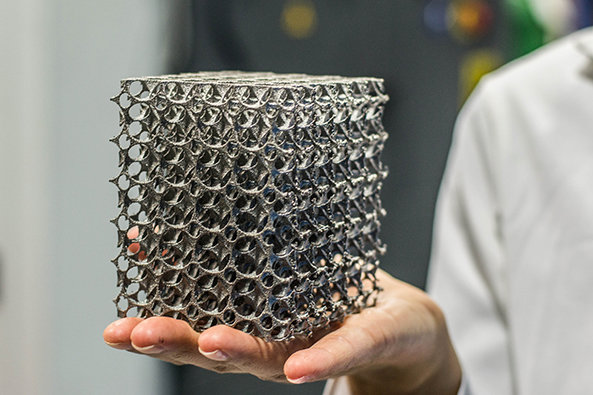

Producing the complex parts

It has the ability to manufacturing the objects with geometries.

Why Do We Need This Process

3D printing helps us visualize how to work in a faster and cheaper way. It means that the alternations of design can be done efficiently during the process. Compared with the traditional manufacturing techniques, it provides more possibilities for entrepreneurs. Besides, the 3D printed parts has stronger strength and durability.

How Long Would it Take to Complete the Process

Overall printing time is affected by the object’s dimension, size and the printing parameters. The completed part’s condition is also essential for considering printing duration, as better-quality goods take forever to make. Additive Manufacturing can require anything from those few minutes to many minutes or hours, depending on the pace, resolution, and content.

Post Processing of Additive Manufacturing

Although additive manufacturing seems exceptionally flexible, it has some specific limitations. It seems that post-processing can be one of the key bottlenecks in it. Post-processing is the essential final step for the 3D printing that can improve quality of the surface. We need to figure out these problems by turning it into automation so that it enables the viable use in production.

How Financially Downstream Occur With This Process

Aside from providing clients with supply chain management and cost advantages, putting a machining shop around the corner to its printer operations offers 3rd dimension with an existentialist benefit. Said it raises the likelihood of the organization’s ultimate survival.

Design Tips

To test and assess a prototype before entering into full production mode, components created by quick tooling are ideal.

Case Study

These case studies comprises all the details about the project and how we implemented our skills to give out the best result.

Ready to start your next project?

Contact us and get a quote in 24 hours