Prototype Services

As fast as 1 week

No Minimum Order Quantities

Tight Tolerances

Rapid, Innovative, Smart Engineering Services

At Rise Prototype, we are dedicated to offering the highest design to assist you in achieving your any industrial design demands. You can start your new project through the most professional services that we provide. Our worldwide team of engineers, designers, technicians and professionals would try their best to take your product’s thoughts to life via the advanced equipment and techniques. Therefore, we provide an ideal atmosphere for successfully integrating multiple disciplines, culminating in practical benefits and bringing revolutionary items to market quickly and accurately.

CNC Machining

CNC machining is a manufacturing process that involves a pre-programmed software system directing tools and machines. It is a popular way to make metal prototypes or plastic ones. There are several types of tools like 3 to 5 axes. High accuracy and precision are its major benefit that we can bring from this technique. Probably its variability could accommodate the demands of entrepreneurs.

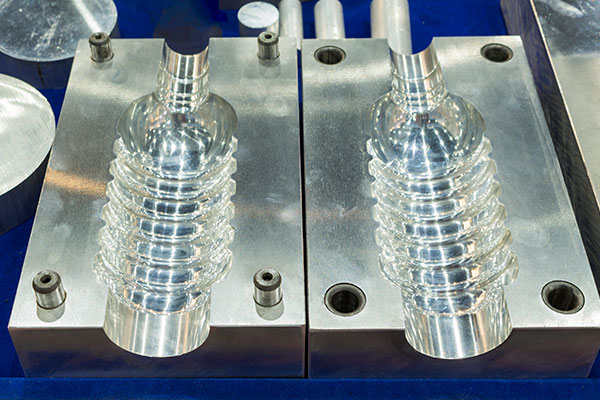

Plastic Injection Molding

Injection molding is the ingredients used to create workpieces for design examination. Reduced lead time increases the expense of such a process, so quick injection molding is no exception. It is the most common-used method for plastic parts. It involves a high-pressure injection of molten plastic materials into the mold. It is a fantastic trait to have when trying to achieve brand consistency & part dependability in big volume production.

Rapid Tooling

Rapid tooling has been a significant development within applications used. It is actually pared back injection molding that enables you to get parts quickly and with lower costs. There is more output as compared to other manufacturing processes and the mold can produce a large number of products without wearing out. Besides, this method can consolidate the complex assembly processes into one process.

Vacuum Casting

Vacuum casting uses silicone molds to make plastic and rubber components under the condition of vacuum. Pressure cast parts have dimensionally correct, accurate duplicates of the original pattern, including features and texture, perfectly replicated. It fits for small quantities of functional parts’ production. If you have a desire of making a prototype or a demo and function testing, vacuum casting may be an ideal option for you.

Sheet Metal

Sheet metal allows you to accomplish multiple jobs quickly and efficiently, including cutting, pressing, bending, puncturing, ironing, rotating, deep drawing, rolling making, press brake trying to form, moves to spin, etc. It is widely used material across various industries. Due to its durability and tensile strength, this technique can be precisely manipulated. Steel, aluminum, copper, brass can be the materials of this technique.

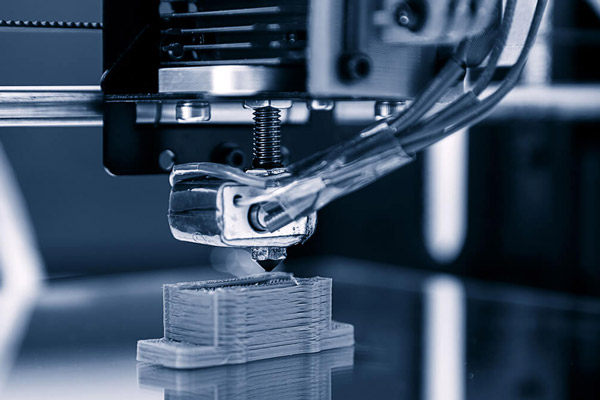

Additive Manufacturing

Additive manufacturing, otherwise referred as 3D printing is a process that builds a part layer by layer. Additive procedures remove material for form components, whereas additive production methods add layers of fabric to construct things. This manufacturing method has revolutionized manufacturing industry by giving business to a one-step technology. It might be tough to grasp how to use each technology to maximize product design and expansion.

Surface Finishing

Various articles and finishing processes can increase machine components’ surface roughness, aesthetic qualities, and fatigue strength. Smoothing or polishing machined items can enhance surface quality & attractiveness by minimizing surface roughness. Help smooth or polishing can remove some material, impacting the part’s dimensional accuracy.

At Rise Prototype, you can know more prevalent finishing methods so you can choose the best one for a particular application.

Design Tips

To test and assess a prototype before entering into full production mode, components created by quick tooling are ideal.

Case Study

These case studies comprises all the details about the project and how we implemented our skills to give out the best result.

Ready to start your next project?

Contact us and get a quote in 24 hours