Injection molding is a leading process involved in plastics mass manufacturing. The Plastic injection molding process consists of designing, engineering, molding, and producing a range of products across many industries.

The process is easy to scale for manufacturers, making it highly versatile and suitable for mass-production environments. Many industries use plastic molded parts, and the refinement of the technology allows manufacturers to produce huge quantities of products with accuracy, speed, and precision.

How an Injection Molding Machine Works

Plastic injection molding machinery varies in size but uses the same process. The size of the machine depends on the specifications and requirements for use, as do the types of molds.

It starts with pushing thermoplastic pellets through a hopper, melting them into a mold under high pressure before cooling the material into a specific shape. There are several resins and additives manufacturers can combine in the process to create any design feature.

It’s a simple process, allowing the mass manufacturing of products in short periods. As a result, manufacturers benefit from economies of scale, bringing affordable products to market in various industries.

Why Injection Molding Is Popular with Product Manufacturers

Many products use the plastic injection molding process. It offers the following advantages in manufacturing.

- Excellent Precision & Accuracy – It’s possible to create many different molds in any shape without compromising tolerances in product design.

- Speedy production capability – Molds can produce products or parts in volume at cost-effective prices.

- Reliability & Longevity – Molds are highly durable and withstand thousands of cycles without needing maintenance or replacement.

- Versatility – Engineers can produce molds in basic or intricate designs.

The high accuracy in plastic molding production creates tolerances within 0.005 inches (0.127mm). You get an unbelievably fast manufacturing time, with 15 to 30 seconds between cycles, and up to 25X savings over plastic machining manufacturing processes.

The flexibility of plastic injection molding allows manufacturers to effortlessly change the material produced and the product colors. The addition of fillers reduces plastic density, allowing for the production of durable, high-strength products and components with a smooth finish.

What Markets & Products Use Plastic Injection Molding?

Isaiah and John Hyatt invented the plastic molding machine in 1872, with its use growing exponentially in the modern era. In the past, plastic molding machines could only produce basic items like hair combs and buttons, but today, the technology can manufacture intricate parts for many industries.

Here are some industries where you’ll find plastic molded parts and products.

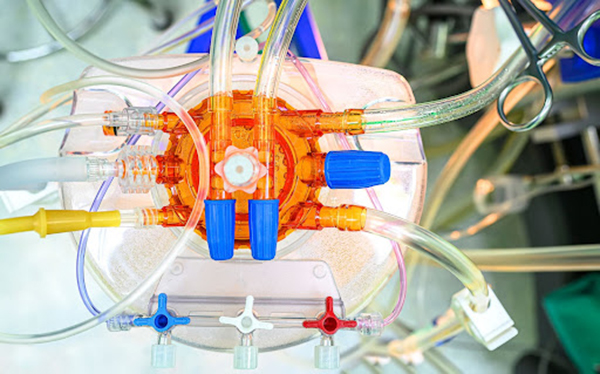

- Medical

- Industrial

- Aerospace

- Automotive parts

- Life Sciences

- Sports equipment

- Electronics & Computer hardware

- Housing for small household appliances

- Automotive

- Toys

- Kitchenware

- Bottles & Bottle Caps

- Vinyl home siding and windows

- Flower Pots

- Wardrobe Products

Plastic molding allows repeatable quality in product manufacturing. For instance, LEGO blocks are plastic molded, and the consistency and accuracy of the blocks never falter. Every piece is identical in size, shape, color, and interlocking capability. You’ll never have an issue with pressing LEGO blocks together due to the repeated quality and consistency involved in the production process.